-

FIRE PROTECTION

- FIREFLEX® VACTEC

Vacuum-Based Fire Protection Technology

FireFlex®’s VACTEC® Vacuum Fire Protection System is a complete FM approved integrated system that offers unique features and benefits such as corrosion mitigation measures and elimination of water columns and ice plugs.

Benefits of the FireFlex® VACTEC® Units

Vacuum technology provides inherent corrosion inhibiting capability by removing oxygen and moisture from the piping.

Fully assembled, factory tested and ready to be connected to the water supply and piping network, system includes all control valves, a vacuum pump, release control panel and the unique FireFlex® FLX-PC Vacuum Pressure Controller which constitutes the heart of the system.

Unique Features

- Inhibiting atmosphere quickly created as you set-up the system

- Automatic elimination of water columns preventing ice plugs formation

- Fast activation after sprinkler operation through patented FLX-PC controller

- Real-time vacuum pressure monitoring insuring constant corrosion mitigation

- Sprinkler system reliability and performance maintained thru system lifetime

- Use of black steel pipe in dry-pipe systems permitted by FM when using vacuum systems

- Easy on-site reconfiguration

- Low maintenance cost

The VACTEC® Cabinet

Factory assembly of the VACTEC® cabinets ensures that all components have been carefully integrated. All systems are fully programmed and tested at the factory which facilitates the onsite installation and commissioning process.

The FireFlex® cabinets are of the freestanding type and are made of robust 14 gauge steel with a corrosion resistant fire red paint finish, polyester powder-coated and oven-baked on a phosphate base. Cabinets are also provided with two locked frontal doors that are removable without special tools, reducing space requirements for ease of installation and maintenance. Furthermore, all doors are provided with a neoprene gasket to reduce vibrations.

Technical details:

- Factory assembled, programmed and tested under ISO-9001 standards

- Uses the Viking Model F-1 Straight Through Deluge valve

- Comes standard prewired to the Viking VFR-400 releasing control panel

- Compact, aesthetic and easy to move

- Neoprene gasket on all doors to eliminate vibrations

- No open drain cup inside unit

- Separate unlocked access hatch to emergency manual release

- Serial number on every unit for easy reference

- User-friendly standardized owner’s manual with every unit

FireFlex® FLX-PC Controller

The patented FLX-PC device is used to precisely monitor and control the vacuum level in the piping network, display the vacuum pressure, vacuum pump run time and frequency of pump operation, in real time, thus providing useful information in regards to major changes in the piping network.

The FLX-PC Vacuum Pressure Controller controls the vacuum pump and is programmed to maintain vacuum pressure in the piping network between -180 mbar (-2.6 psi) and -150 mbar (-2.2 psi).

The piping network within the FireFlex®’s Vacuum Fire Protection System is supervised by the FLX-PC for vacuum pressure under normal conditions. In case of a fire, it will

detect a sprinkler activation, generate an alarm and trip the system in less than 5 seconds. The FLX-PC also supervises the vacuum pressure for low and high levels and supervisory signals are provided.

Multiple Models and Available Configurations

Our adaptability, in order to better meet our customers' needs, is our main priority.

Available Configurations

FireFlex®’s Vacuum Fire Protection Systems are available in Dry-pipe Vacuum and Pre-action Vacuum, Non-Interlocked, Single Interlocked and Double Interlocked configurations in sizes from 3” to 8” and all use the same components making it easy to order.

Preaction

- Non-interlocked

- Single interlocked

- Double interlocked

Dry Pipe

- Available in standard 175 psi or HP 250 psi

Dimensions FireFlex®-VACTEC® Units

| SYSTEM SIZE | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| 3" | 4" | 3" | 2" | 46" | 25" | 77" |

| 4" | 4" | 4" | 2" | 46" | 25" | 77" |

| 6" | 6" | 6" | 2" | 46" | 25" | 77" |

| 8" | 8" | 8" | 2" | 54" | 31" | 81" |

Note : Dimensions and actual size may vary depending on options and configuration selected, please refer to data sheets for exact dimensions.

What FireFlex® VACTEC® units are made of?

FireFlex systems are made of industry-recognized components. We’re proud to work with these amazing partners.

Renowned Control Panel

The Viking VFR-500 is cULus Listed, FM Approved and meets UL 864-9 requirements. It features onboard menu-driven programming with twelve pre-installed programs to facilitate set up.

The panel is compatible with multiple initiating devices such as: linear heat detection, smoke and heat detectors, waterflow indicators, low & high air pressure switches as well as manual pull stations.

Aligned with key NFPA Requirements

We are actively involved in supporting and training the fire protection practitioner at all levels—including industry-related associations such as NFPA, SFPE, AFSA, NFSA and ASPE.

Releasing Circuit Disconnect Switch

Required by NFPA 72 - 2010 Edition, this feature is standard on all our FireFlex® VACTEC® units and prevents accidental discharge during maintenance or inspection. Operation of the key switch physically disconnects the release circuit wiring and causes a trouble signal at the releasing control panel.

Why trust the FireFlex team and its systems?

Our cutting-edge systems are an alliance between research, development, quality & durability.

BECAUSE WE ARE INDUSTRY PIONEERS

Since its inception in 1991, FIREFLEX SYSTEMS has been designing and manufacturing state-of-the-art innovative integrated fire protection systems that set the benchmark in the market.

FOR THE WIDEST SELECTION AVAILABLE ON THE MARKET

FIREFLEX SYSTEMS offers the widest selection of integrated systems on the market. Regardless of the hazard to be protected, FIREFLEX is able to offer the best available technology with the widest range of options to suit all needs.

FOR OUR QUALITY CONTROL

FIREFLEX SYSTEMS' commitment, year after year, to quality and continuous improvement has resulted in achieving and maintaining its ISO 9001 quality certification. Its modern facilities are geared towards producing a high-volume of quality integrated systems in a factory-controlled setting.

FOR OUR TECHNICAL SUPPORT

Whether it is through exhibits, conferences, lunch & learn presentations, technical seminars, Webinars or one-on-one technical discussions, FIREFLEX's technical sales representatives draw on their in-depth knowledge and expertise to provide a level of technical support that meets or exceeds customer expectations.

FOR OUR CUSTOMER SERVICE

Our customer service department is readily available to address any product related service call, replacement part or general operation and maintenance questions that may arise. All our integrated product lines possess a serial number which is entered into our database. This enables FireFlex to record and track service calls, replacement parts, or any system modifications that have been reported on individual units.

FOR OUR INNOVATIVE PRODUCTS

Actively involved with research and development, FIREFLEX embarked on a new endeavor to better serve the fire protection practitioner in addressing challenging fire protection scenarios that evolve in modern life.

CORROSION INHIBITION

Negative pressure-based FireFlex®’s VACTEC® system and its vacuum technology provides inherent corrosion inhibiting capability by removing oxygen and moisture from the piping.

Economical & Efficient long-term Solution

It offers an economical and long term solution on applications where piping corrosion, clogging or ice plugs can affect system performance or where maintenance issues are a concern.

The inhibiting atmosphere is quickly created, only a few minutes after you start the system, normal vacuum pressure is reached thus creating the proper atmosphere to inhibit corrosion. The system pressure is then monitored in real-time by the FLX-PC controller ensuring a proper level at all times.

C Factor

For corrosion mitigation measures, it is important to ensure that water is kept out of the piping network during its standard operation or supervisory mode. C-value of 120 can be used for design purposes when such measures are able to be fully implemented as outlined in FireFlex®’s design manual.

Suitable Applications

Integrated Vacuum Fire Protection Systems can be used to protect all applications requiring the following types of systems: The corrosion mitigation properties of the Vacuum technology make this technology suitable for all applications where piping corrosion or pipe clogging is a concern.

- Large parking garages where corrosion is often a concern.

- Freezer protection is also a suitable application, where no ice plugs are formed in the piping network

- The vacuum pump removes residual water in the riser each time it operates to maintain the proper vacuum level. No condensation problems occur, and no additional special equipment is required.

- Storage applications where not heating the building can significantly reduce operational costs.

- Mission critical and sensitive areas where water damage is a concern. Leaks in the piping network will not allow water droplets to escape, vacuum pulls air from outside and water, if any, will stay in the piping network.

APPROVALS & STANDARD LISTING

Sprinklers For Vacuum System

Sprinklers must be approved and tested for use under vacuum condition. Contact FireFlex® for complete list of approved sprinklers or refer to sprinkler manufacturer’s datasheets.

VACTEC system now supports dozens of sprinkler types, here's a quick list.

| Model | K | Type | Response | NPT |

| VK 1001 | 5.6 | Upright | SR | ½" |

| VK 3001 | 5.6 | Upright | QR | ½" |

| VK 2001 | 8.0 | Upright | SR |

¾" |

| VK 2002 | 8.0 | UprightR | SR | ½" |

| VK 3501 | 8.0 | Upright | QR |

¾" |

| VK 3502 | 8.0 | UprightR | QR |

½" |

| VK 598 | 25.2 | Upright | SR |

1" |

| VK 1021 | 5.6 | Pendent | SR | ½" |

| VK 3021 | 5.6 | Pendent | QR | ½" |

| VK 2021 | 8.0 | Pendent | SR | ¾" |

| VK 2022 | 8.0 | Pendent | QR |

½" |

| VK 3521 | 8.0 | Pendent | QR |

¾" |

| VK 3522 | 8.0 | Pendent | QR |

½" |

| VK 4921 | 5.6 | Pendent | SR |

½" |

| VK 4621 | 5.6 | Pendent | SR & QR |

½" |

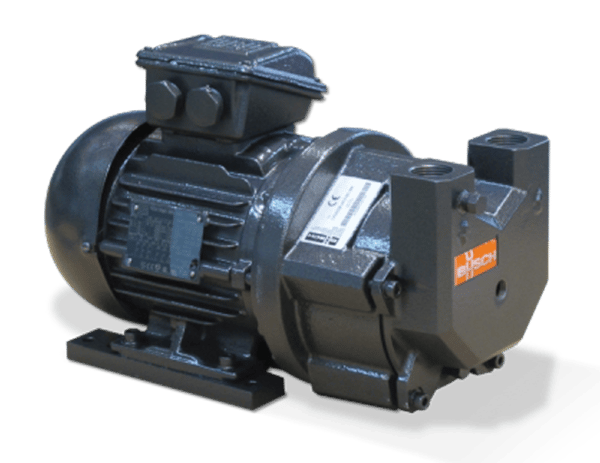

Riser Shut-off Valve & Vacuum Pump

For easier maintenance the riser shutoff valve comes as a standard on all units. As for the vacuum, it is created using a water ring seal vacuum pump controlled by the FLX-PC.

Riser Shut-off Valve

It consists of a supervised butterfly valve which allows for a full flow trip test without flooding the system’s piping and a sight glass located on the main drain for visual indication of the water flow.

Vacuum Pump

The vacuum is created using a (1.5 HP, 208V-240V/60Hz 7 Amps) water ring seal vacuum pump controlled by the FLX-PC.

The vacuum pump used in the system allows for very quick startups. The required time to establish maximum supervisory vacuum level in the piping network is less than 4 minutes for a 1000 gallon system thus saving start-up and maintenance time in the field.

Quiet running and minimal vacuum pump maintenance requirements offers significant advantages compared to air compressors.

FIREFLEX® Vactec® Certificates & Tools

The FireFlex® Vactec® units are FM Approved.

Click on the links below to view the FIREFLEX®-Vactec® certificates:

- FM Approval (See Certificate)

Talk To A Fire Protection Expert

Whether you want to select, specify, install or maintain our systems, you'll find in this section a range of useful documents related to our integrated systems. For further information, do not hesitate to contact our team of experts.